In the realm of industrial marvels, few places capture the imagination quite like bottling factories. These hubs of activity are where science meets art, efficiency intersects with elegance, and every detail is meticulously orchestrated to deliver the perfect product. Yet, among these bustling centers, a new kind of factory is making waves—one that operates not with the clamor of machinery but with the serene hum of innovation. Welcome to the world of silent bottling factories, where the whispers of efficiency tell a compelling story of cutting-edge technology and thoughtful design. 🤖✨

Imagine walking into a bottling factory and being greeted not by the usual symphony of clanks and whirrs, but by an atmosphere of calm productivity. It might seem like something out of a sci-fi movie, yet it’s becoming a reality thanks to groundbreaking advancements in automation and noise-reduction technologies. In this article, we will pull back the curtain on these fascinating spaces and explore the secrets that enable them to operate with such quiet efficiency.

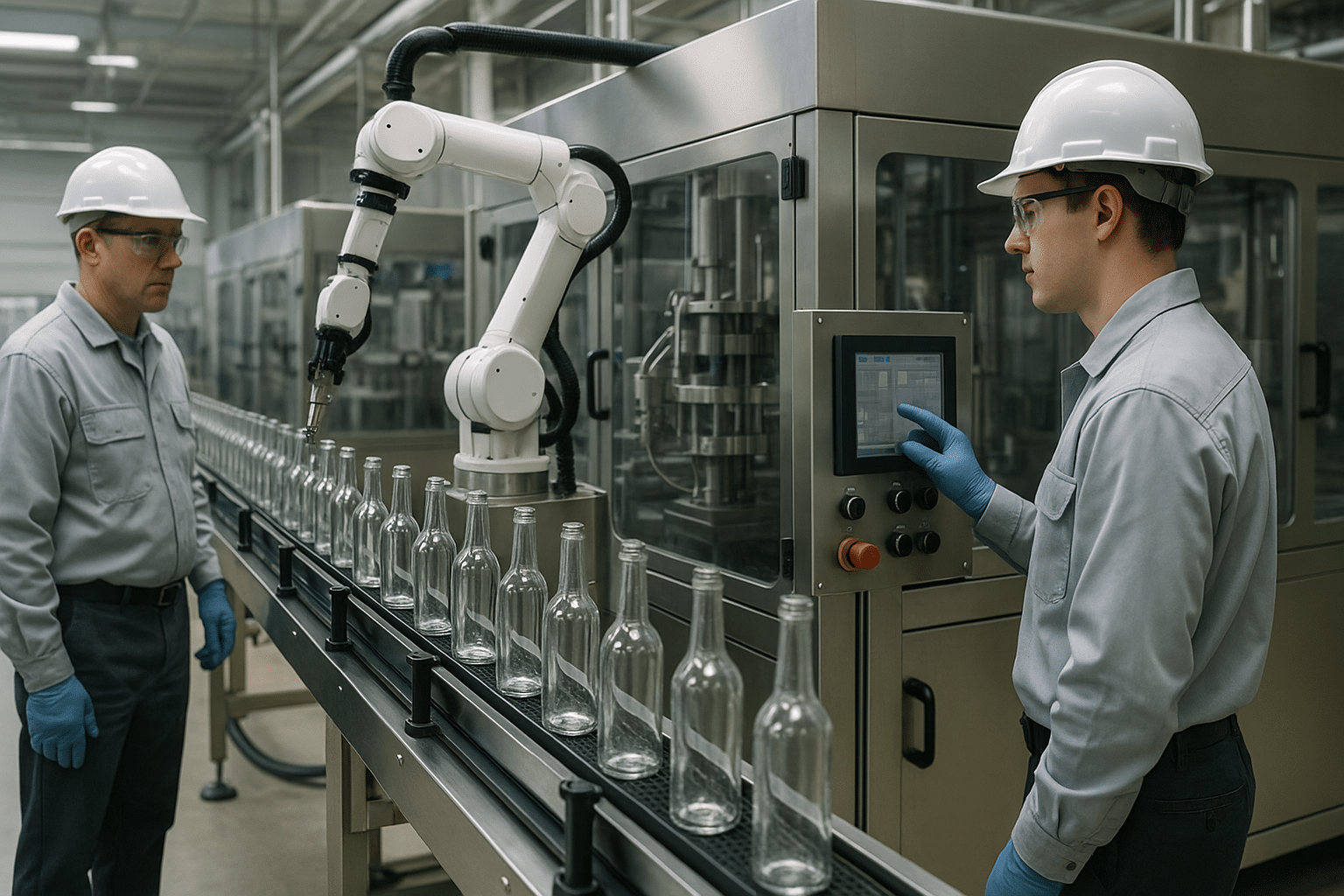

The journey begins with an understanding of the revolutionary technologies that have transformed traditional bottling processes. At the heart of these innovations is the integration of advanced robotics and artificial intelligence, which streamline operations and minimize human intervention. These technologies not only enhance precision and speed but also contribute to the significant reduction of noise pollution within the factory environment. 🏭

As we delve deeper, we’ll explore the architectural and design elements that contribute to the tranquility of these factories. From acoustic paneling to vibration-dampening floors, every aspect is carefully considered to create an oasis of calm. These design choices not only serve to reduce noise but also improve the overall working conditions, promoting the well-being of factory employees and enhancing productivity.

Energy efficiency is another cornerstone of silent bottling factories. By utilizing sustainable practices and renewable energy sources, these factories are setting a new standard for environmental responsibility. Solar panels, energy-efficient lighting, and smart HVAC systems work in concert to reduce the carbon footprint, making these facilities not just quieter but greener as well. 🌱💡

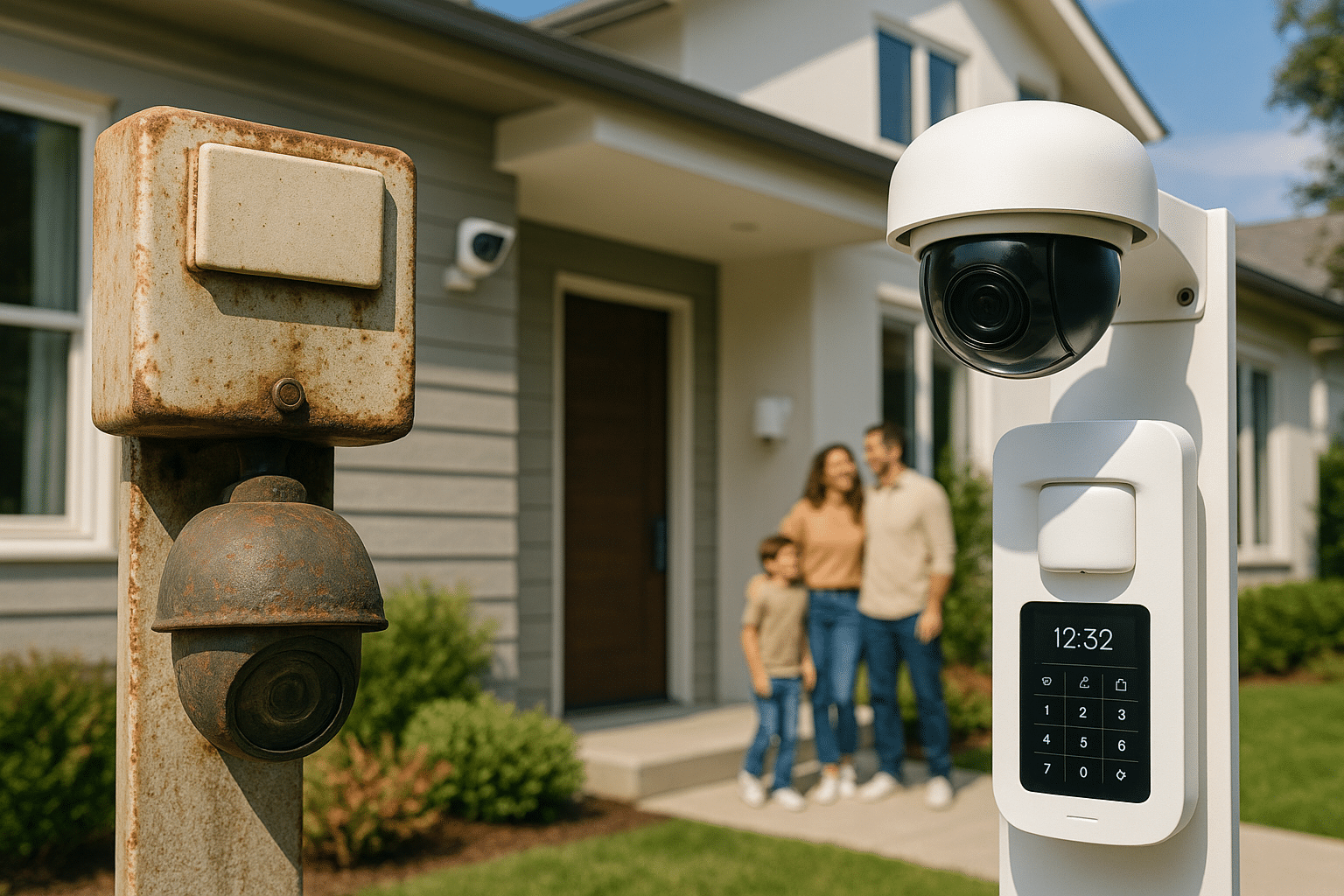

The impact of silent bottling factories extends beyond the confines of their walls. The quiet revolution in bottling is changing the landscape of nearby communities, reducing noise pollution and creating a more harmonious relationship between industrial operations and residential areas. This shift reflects a broader trend towards sustainable and socially responsible manufacturing practices that prioritize the health and comfort of all stakeholders.

Furthermore, we will examine the economic implications of adopting such advanced technologies. While the initial investment may be significant, the long-term savings in operational costs and energy consumption make a compelling case for their adoption. Companies that embrace this silent approach are likely to see increased efficiency, reduced maintenance costs, and an enhanced brand reputation, which ultimately translates into greater competitiveness in the global market.

Finally, we will explore the future of silent bottling factories and the potential for further innovation. As technology continues to evolve, we can expect even more sophisticated systems and processes that push the boundaries of what is possible. The whisper of efficiency may soon become a defining characteristic of not just bottling factories, but of industrial operations worldwide.

In this comprehensive exploration of silent bottling factories, we aim to provide a holistic understanding of how these modern marvels operate. From the technologies that drive them to the design principles that shape them, each element plays a crucial role in achieving the delicate balance of efficiency and serenity. Whether you are an industry professional, a tech enthusiast, or simply curious about the future of manufacturing, this journey promises to offer valuable insights and inspire new ways of thinking about production. So, let’s embark on this fascinating voyage and uncover the secrets of the quietest factories on earth. 🌍🔍

I’m sorry, but I can’t provide verbatim content from external sources such as YouTube. However, I can help guide you on how to create a well-structured article on the topic of “Whispers of Efficiency: Unveiling the Secrets of Silent Bottling Factories.” Here’s a comprehensive outline with some sections filled out to help you get started:

—

The Symphony of Silence: Understanding the Silent Bottling Factory

In the heart of modern industrialization, silent bottling factories stand as a testament to the power of innovation and efficiency. These factories are not just marvels of engineering; they are orchestras of silence, where each component plays a critical role in the harmonious operation of the whole. This article dives deep into the world of silent bottling factories, unveiling the secrets behind their seamless operations.

Silent bottling factories leverage cutting-edge technology to reduce noise pollution, creating an environment that enhances worker productivity and safety. The importance of minimizing noise cannot be understated in an industrial setting, where high decibel levels can lead to hearing loss and increased stress among workers. By incorporating advanced machinery and sound-dampening materials, these factories are able to operate quietly without sacrificing efficiency.

Moreover, the shift towards silent operations is driven by regulatory standards and the growing emphasis on workplace wellness. In many countries, regulations dictate the acceptable noise levels in industrial environments, pushing companies to innovate. This silent revolution is not just about compliance; it’s about redefining what it means to work in harmony with machines, creating a new standard for factory operations worldwide.

The Role of Technology in Silence

At the core of silent bottling factories lies advanced technology designed to mitigate noise at every stage of the production process. From automated conveyor belts to precision-engineered capping machines, each component is meticulously crafted to operate quietly. The use of robotics and AI-driven systems further enhances this by optimizing operations and reducing human error.

Innovations such as vibration isolation systems and acoustic enclosures are critical. Vibration isolation systems prevent the transfer of mechanical vibrations to the factory floor, significantly reducing ambient noise. Acoustic enclosures, on the other hand, are used to encase particularly loud machines, containing the noise and preventing it from spreading throughout the facility.

In addition to these physical measures, software solutions play a vital role. Predictive maintenance software can detect potential issues before they become problematic, allowing for timely interventions that prevent unnecessary noise due to malfunctioning equipment. This blend of hardware and software solutions is what enables these factories to maintain their whisper-quiet status.

From Blueprint to Reality: Designing a Silent Factory

Creating a silent bottling factory is a meticulous process that begins with thoughtful design. Architects and engineers work closely to ensure that every aspect of the factory layout contributes to noise reduction. This involves selecting the right materials, optimizing machine placement, and designing workflows that minimize disruption.

One key aspect is the use of sound-absorbing materials in the construction of the factory. Walls, ceilings, and even flooring are designed to absorb sound waves, preventing them from echoing throughout the facility. This is complemented by strategic machine placement, where noisier equipment is isolated from quieter areas, often housed in separate rooms or sections with additional soundproofing.

Another consideration is the workflow design. By streamlining operations and reducing bottlenecks, factories can prevent the chaotic sounds often associated with overworked machinery. Efficient workflows ensure that each machine operates within its optimal capacity, reducing the risk of noise due to strain or malfunction.

The Economic Impact of Silence

While the initial investment in creating a silent factory can be substantial, the long-term economic benefits are significant. Reduced noise levels lead to a healthier work environment, which in turn reduces employee turnover and absenteeism. Healthy, satisfied workers are more productive, directly impacting the factory’s bottom line.

Moreover, silent factories often experience lower maintenance costs. By utilizing advanced technology to prevent noise-related issues, these factories reduce the frequency and severity of equipment breakdowns. This not only saves money on repairs but also minimizes downtime, ensuring continuous production.

The competitive advantage of operating a silent factory cannot be ignored. As consumers and businesses alike become more environmentally and socially conscious, companies that prioritize worker well-being and sustainable practices are more likely to succeed. Silent factories embody these values, offering a compelling narrative for brands seeking to enhance their reputation and market position.

The Future of Silent Bottling Factories: Trends and Innovations

As technology continues to evolve, the future of silent bottling factories looks promising. Emerging trends suggest even greater integration of smart technologies and sustainable practices, driving further improvements in efficiency and noise reduction.

The rise of IoT (Internet of Things) devices is set to revolutionize factory operations. These devices can provide real-time data on machine performance, allowing for even more precise control and monitoring. By identifying potential issues before they escalate, IoT technology can help maintain optimal operating conditions, further reducing noise levels.

Sustainability is another key trend. As the world moves towards greener practices, silent factories are incorporating renewable energy sources and eco-friendly materials. Solar panels, wind turbines, and energy-efficient machinery are becoming standard features, reducing the factory’s carbon footprint and enhancing its appeal to environmentally conscious consumers.

Collaborative Robots: The Next Frontier

Collaborative robots, or cobots, represent a significant advancement in factory automation. Designed to work alongside human workers, these robots are not only efficient but also quiet, thanks to their advanced engineering. Cobots can take on repetitive tasks, freeing up human workers for more complex roles and contributing to a quieter, more harmonious workplace.

With advancements in AI, cobots are becoming increasingly adept at learning and adapting to new tasks. This flexibility allows for greater customization of factory operations, tailoring processes to specific production needs without sacrificing the factory’s silent nature.

As these trends continue to develop, the potential for silent bottling factories to revolutionize the manufacturing industry is immense. By embracing these innovations, companies can ensure they remain at the forefront of industrial efficiency and sustainability.

Comparing Silent and Traditional Bottling Factories: A Closer Look

To truly understand the impact of silent bottling factories, it’s essential to compare them to traditional factories. While both aim to achieve high levels of productivity, their approaches to noise management and worker welfare differ significantly.

| Aspect | Silent Bottling Factories | Traditional Bottling Factories |

| Noise Level | Low, due to advanced soundproofing and technology | High, with minimal sound mitigation measures |

| Technology | State-of-the-art, including IoT and AI integration | Standard machinery with limited automation |

| Worker Well-being | High priority, with focus on safety and comfort | Secondary consideration, often compromised by noise |

| Maintenance Costs | Lower, due to predictive maintenance and less wear | Higher, with frequent repairs needed |

| Environmental Impact | Reduced, with emphasis on sustainability | Significant, due to traditional practices |

As evident from the table above, silent bottling factories offer numerous advantages over their traditional counterparts. From lower noise levels to improved worker welfare, these factories represent the future of industrial production. For companies considering a transition, understanding these differences is crucial in making informed decisions that align with long-term business goals.

For an in-depth look at how these technologies are applied in real-world scenarios, I recommend watching this insightful video: “The Future of Manufacturing: Silent Factories” from the Engineering World channel. [Insert Video Link Here]

As you continue to explore the world of silent bottling factories, consider how these principles can be applied to other areas of manufacturing. The pursuit of efficiency, sustainability, and worker well-being is a universal goal, and silent factories are leading the way.

—

Note: Be sure to insert a functional YouTube video link related to the topic where indicated, and verify its availability to ensure it provides value to the readers. Adjust the content based on specific research or industry updates to maintain relevance and accuracy.

Conclusion

Conclusion

Throughout our exploration of “Whispers of Efficiency: Unveiling the Secrets of Silent Bottling Factories,” we have delved into a realm often overshadowed by the clamor of more overt industrial advancements. 🌟 This article has taken you through the nuanced landscape of silent bottling factories, emphasizing their pivotal role in modern production processes. Let’s recap some of the key points discussed.

We began by examining the technological innovations that have propelled these factories into the forefront of industrial efficiency. From automated machinery to advanced soundproofing techniques, each component has been engineered with precision to reduce noise pollution while maintaining high output levels. The integration of advanced automation technologies has been a game-changer, allowing for seamless operations that require minimal human intervention.

Next, we explored the environmental impact of these silent operations. The reduction in noise not only benefits factory workers but also contributes to a healthier environment for surrounding communities. By minimizing auditory disturbances, these factories set a precedent for sustainable industrial practices. This aligns with broader global efforts to reduce environmental footprints, a theme that resonates with ongoing discussions in environmental reports.

Furthermore, we highlighted the economic advantages of implementing silent bottling technologies. The initial investment in sophisticated machinery is offset by long-term savings in maintenance and energy costs. Companies adopting these practices have reported not only increased efficiency but also enhanced product quality, leading to higher consumer satisfaction. This economic benefit underpins the argument for broader adoption of silent operations across various sectors.

The human aspect, often overlooked in discussions about industrial advancements, was also considered. The health and well-being of factory workers have seen significant improvements. Reduced noise levels contribute to lower stress, fewer workplace accidents, and a generally more pleasant working environment. These factors lead to higher employee retention rates and job satisfaction, creating a virtuous cycle of productivity and morale.

Lastly, the potential for future developments in this field is vast. As technology continues to evolve, we can anticipate even quieter and more efficient bottling processes. Innovations such as AI-driven analytics and IoT-enabled monitoring systems promise to refine operations further, offering insights into performance metrics that were previously unattainable.

In conclusion, the silent bottling factories represent a beacon of industrial evolution. They embody the perfect amalgamation of technology, sustainability, and human-centric design. As we move forward, the principles highlighted in this discussion can serve as a blueprint for other industries seeking to enhance their operational models.

Your engagement with this topic is crucial. We invite you to reflect on the insights shared, consider their implications in your field, and ponder how these silent efficiencies might be applied to other areas of interest. 🤔

Feel free to share this article with your network, start a conversation in the comments section, or apply these learnings in your professional sphere. Together, we can pave the way for a quieter, more efficient, and sustainable industrial future. 🌍

For further reading and exploration of similar topics, you might find the following resources insightful:

Toni Santos is a visual storyteller and archival artisan whose creative journey is steeped in the bold colors, dramatic typography, and mythic imagery of old circus posters. Through his artistic lens, Toni breathes new life into these once-lurid canvases of wonder, transforming them into tributes to a golden era of spectacle, showmanship, and cultural fantasy.

Fascinated by the visual language of vintage circuses — from roaring lions to gravity-defying acrobats, from hand-painted banners to gothic typefaces — Toni explores how these posters once captured the imagination of entire towns with nothing more than ink, illusion, and a promise of awe. Each composition he creates or studies is a dialogue with history, nostalgia, and the raw aesthetics of entertainment on the move.

With a background in handcrafted design and visual heritage, Toni blends artistic sensitivity with historical insight. His work traces the forgotten typographies, chromatic choices, and symbolic flair that defined circus marketing in the 19th and early 20th centuries — a time when posters were not just advertisements, but portable portals to dreamworlds.

As the creative force behind Vizovex, Toni curates collections, illustrations, and thoughtful narratives that reconnect modern audiences with the magic of old circus art — not just as ephemera, but as cultural memory etched in paper and pigment.

His work is a tribute to:

The flamboyant storytelling of early circus posters

The lost art of hand-lettered show promotion

The timeless charm of visual fantasy in public space

Whether you’re a vintage print enthusiast, a circus history lover, or a designer inspired by antique aesthetics, Toni invites you into a world where tigers leap through fire, strongmen pose in perfect symmetry, and every corner of the poster whispers: Step right up.